Here you will see the manufacturing processes of mass-production type of our knives. Press-out method is used, with combination of traditional technique and modern automation. In addition, experienced master craftsman carefully pays attention on all processes in order to maintain steady quality.

Facility Guide

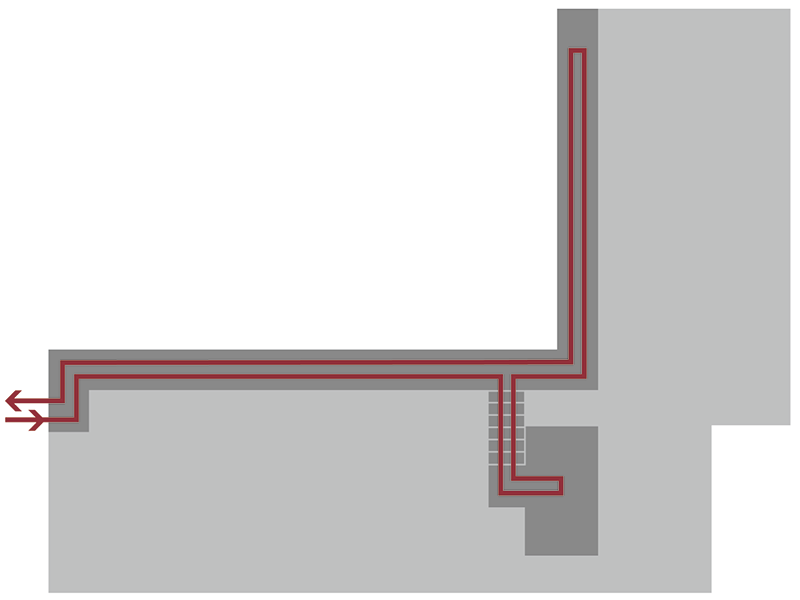

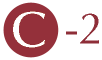

Map and process.

Click on process or alphabet to see pictures.

Hand welding

Hand welding

Weld blade and handle. Good for parts which is too complicated for automatic welding.

Automatic welding

Automatic welding

Weld blade and handle by welding robot. Suitable for mass production.

Grinding and polishing welded part

Grinding and polishing welded part

Evenly and smoothly grind and polish welded part.

Blade polishing

Blade polishing

Hand-polish blade surface that is difficult to be done by machine.

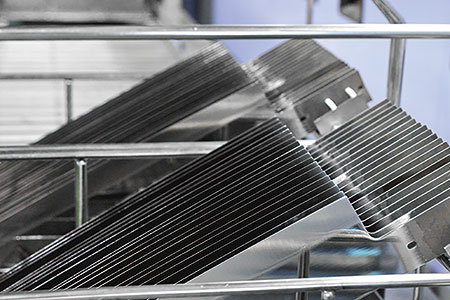

Automatic blade polishing

Automatic blade polishing

Enable blade polishing in quantity at a time.

Hairline processing

Hairline processing

Process hairline finishing on blade surface, that blinds scratches being made while using it.

Washing

Washing

Metal particles and abrasive powder to be washed away by this washing machine.

Flexion press machine

Flexion press machine

Press metal sheet to form or make particular texture pattern. This is typical processing method used for cutlery production which is major industry in our area.

Facility Guide

| A | Hand welding |

|---|---|

| A | Automatic welding |

| B | Grinding and polishing welded part |

| C-1 | Blade polishing |

| C-2 | Automatic blade polishing |

| D | Hairline processing |

| E | Washing |

| * | Flexion press machine |

Hand welding

Hand welding

Weld blade and handle. Good for parts which is too complicated for automatic welding.

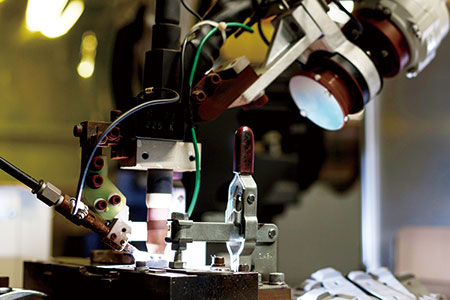

Automatic welding

Automatic welding

Weld blade and handle by welding robot. Suitable for mass production.

Grinding and polishing welded part

Grinding and polishing welded part

Evenly and smoothly grind and polish welded part.

Blade polishing

Blade polishing

Hand-polish blade surface that is difficult to be done by machine.

Automatic blade polishing

Automatic blade polishing

Enable blade polishing in quantity at a time.

Hairline processing

Hairline processing

Process hairline finishing on blade surface, that blinds scratches being made while using it.

Washing

Washing

Metal particles and abrasive powder to be washed away by this washing machine.

Flexion press machine

Flexion press machine

Press metal sheet to form or make particular texture pattern. This is typical processing method used for cutlery production which is major industry in our area.